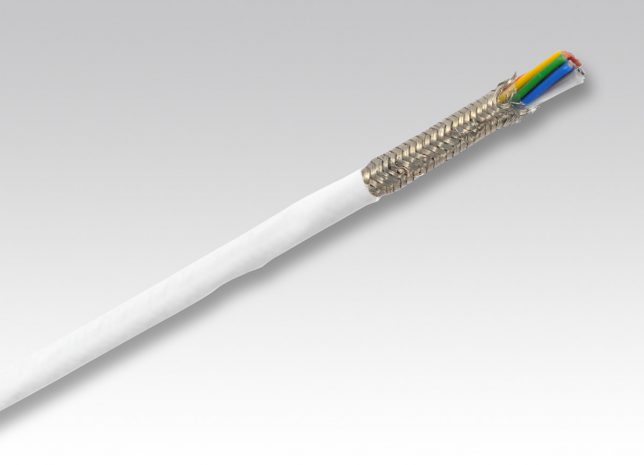

HIFP cables can be used universally thanks to their resistance to high temperatures, aggressive chemicals, fuel and solvents as well as UV radiation. They are silicone-free.

HIFP cables are also suitable for dynamic stress and critical application conditions. They boast a robust, temperature-resistant outer coating.

HIFP cables guarantee a long lifecycle, so cause fewer unplanned downtimes.

Features

Heat & Cold Factor

| Cold-resistant & temperature-resistant | -190° C to +260° C |

Flexibility Factor

| Flexible | Well suited |

| Cable trolley | Conditionally suitable |

| Cable track | Conditionally suitable |

| Spreader | Not specified |

| Torsion | Not specified |

| Reelable | Not specified |

| Robot | Not specified |

Resistance Factor

| Chemicals, solvents | Very suitable |

| Oils, fats | Very suitable |

| UV, ozone, weather | Very suitable |

| Abrasion-resistant | Very suitable |

Typical Applications

Aluminum, steel, iron industry, painting workshops, chemical and petrochemical industry, machine and plant manufacturing, automobile construction, heavy machinery production, iron and smelting industry, steel industry, traffic technology

HIFP – cable variants

- HIFP 155

- HIFP 205

- HIFP 260

- Profibus-Therm

- CAT5-Therm (data bus line)

- CAT6-Therm (Ethernet cable)

The product description reflects the general Alfred Michels GmbH & Co. KG product range. Further custom productions are possible: depending on the design (wire count x cross section), various applications are available ex warehouse, new productions from 100m.

Possible applications should be clarified on a case-by-case basis. Just get in touch. We’d be happy to advise you.