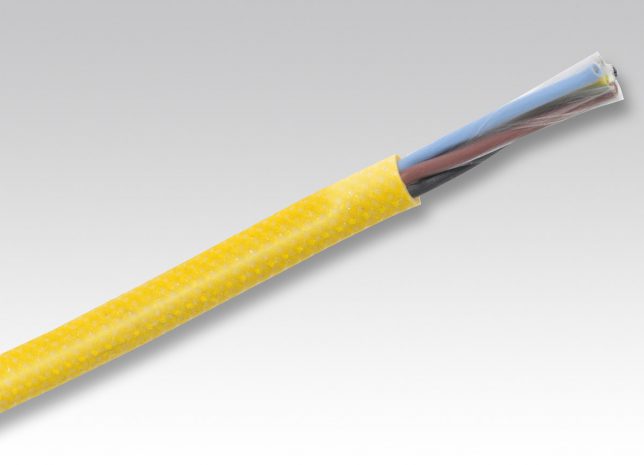

SSID cables have long service lives despite high temperatures. Unlike steel braid cables, they are still flexible. Unlike glass silk coated cables, they offer protection from capillary action when in contact with moisture.

Featuring an outer protective braid, SSID is a practical and safe alternative to other temperature-resistant cables.

Features

Heat & Cold Factor

| Cold-resistant & temperature-resistant | -50° C to +180° C |

Flexibility Factor

| Flexible | Very suitable |

| Cable trolley | Well suited |

| Cable track | Not specified |

| Spreader | Not specified |

| Torsion | Well suited |

| Reelable | Not specified |

| Robot | Conditionally suitable |

Resistance Factor

| Chemicals, solvents | Conditionally suitable |

| Oils, fats | Conditionally suitable |

| UV, ozone, weather | Well suited |

| Abrasion-resistant | Well suited |

Typical Applications

Steel and iron industry, conveyor, hoist and crane technology such as magnet and grab systems, port handling and logistics, recycling

SSID cables

SSID-J

- Synthetic fibers protect the outer coating from mechanical influences e.g. abrasion

- Excellent mechanical and thermal propertiesLightweight and flexible compared to heavy-duty steel braid cables

SSID-O

- Small bending radii

- Halogen-free and low-smoke

- Good resistance to abrasion and notching

- Good UV, ozone and weather resistance

- Moderately resistant to oils and chemicals

- Use as cables for switch cabinets, for power rails, in the steel industry, in machine and plant production, as power cables for high-voltage systems (transformers, generators etc.)

The product description reflects the general Alfred Michels GmbH & Co. KG product range. Further custom productions are possible: depending on the design (wire count x cross section), various applications are available ex warehouse, new productions from 100m.

Possible applications should be clarified on a case-by-case basis. Just get in touch. We’d be happy to advise you.